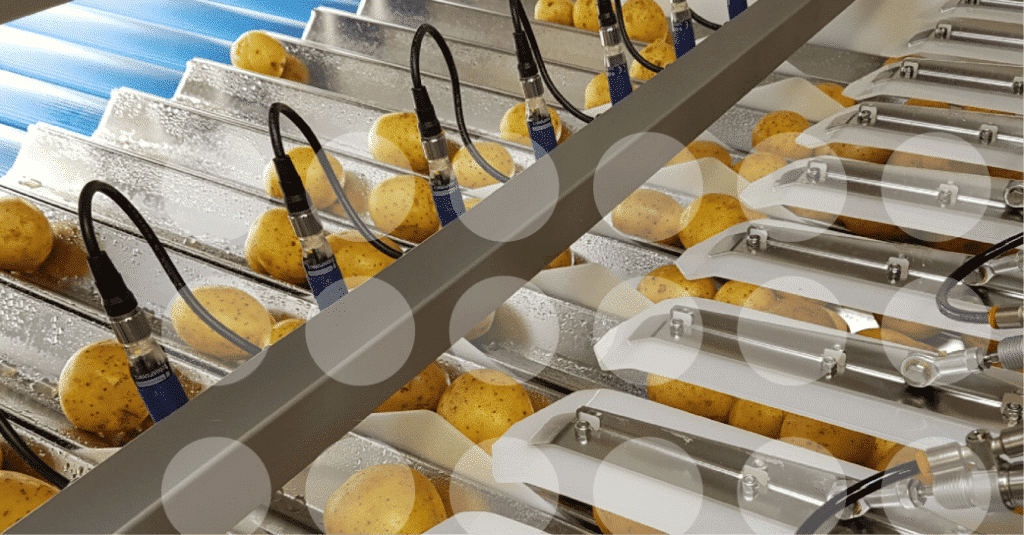

Automatic Optical Inspection

Read more

- ProductsGenerative AI AcceleratorsRecommended blog postAI Vision ProcessorsRecent blog postsAI AcceleratorsSoftware

- ApplicationsAutomotiveSecurityIndustrial AutomationRetailPersonal ComputeAutomotiveRecommended blog postsSecurityDownload our e-BooksIndustrial AutomationCustomer storyRetailCustomer storyPersonal ComputeRecommended blog posts

- Resources

- Company

- Ecosystem