AI-Powered Automatic Optical Inspection

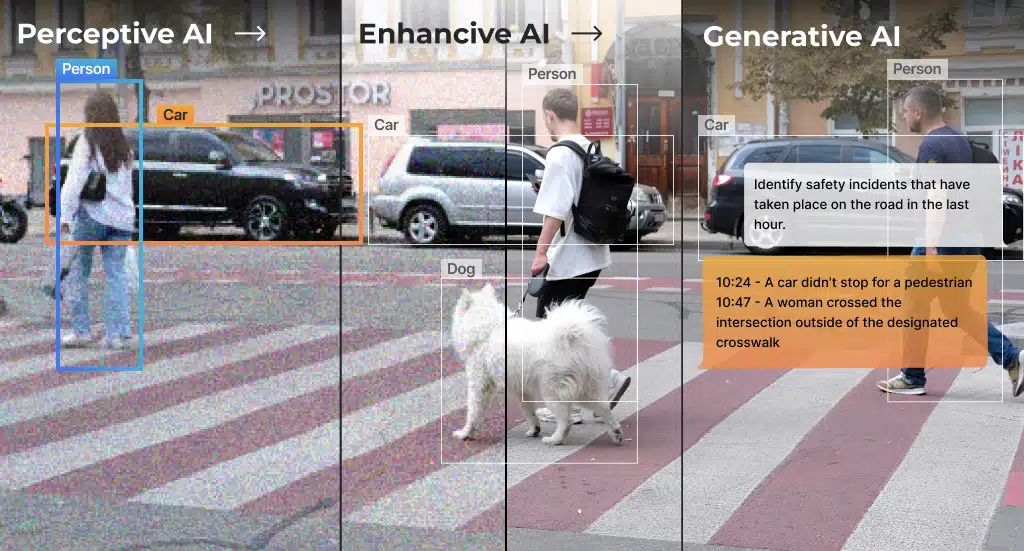

Automated Optical Inspection (AOI) is a cutting-edge technology revolutionizing industrial automation processes. Employed in various manufacturing sectors, AOI plays a pivotal role in ensuring product quality and enhancing production efficiency and productivity. By utilizing high-resolution cameras and advanced image processing algorithms, AOI systems swiftly and accurately inspect and identify each and every manufactured component. The optical inspection can be used for scanning and identifying the manufactured goods, sorting the components, or identifying defects, such as surface abnormalities, misalignments, or missing features. This real-time, non-destructive inspection enables rapid identification and correction of flaws, minimizing costly rework and product recalls. Moreover, it allows handling of large volumes of components with unmatched precision, streamlining production lines, enabling industries to achieve higher productivity, superior quality, and increased customer satisfaction. As technology continues to evolve, Automated Optical Inspection is poised to play an even more crucial role in shaping the future of industrial manufacturing.